Powder Coating

The benefits of powder coating are impressive, but the company that handles your powder coating can make all the difference! Hoosier Coatings can handle large production jobs and large items in our AAMA 2605 CERTIFIED system.

Our state of the art batch ovens are 30 feet long, 10 feet wide, and 10 feet tall. For example, we can handle large automotive frames and large farm equipment. We make sure to take care of each job from the preparation work to the application of the powder coating and the curing or drying of each unique job. Everything we powder coat is extensively cleaned until the best conditions are met for the proper paint adhesion to take place. We have a truly customized system that is made to handle high capacity and custom individual jobs. We are always available to talk with you about your job, big or small.

Serene Aluminum Cabinetry

Our sister company, Serene Aluminum Cabinetry, creates custom and express layout outdoor kitchens. All kitchens feature all aluminum powder coated cabinets that have a 1″ x 1″ tube frame structure and can withstand the elements of outdoor use. Available in almost limitless colors, these cabinets would be highlight of any backyard oasis or outdoor setting. Click here to learn more.

Sublimation Coating

Decoral is a cutting-edge decorative powder coating system able to create amazingly realistic wood grains and custom images on aluminum, steel, iron, glass and countless other materials with complex shapes. Products are initially powder coated. A transfer film, printed with special inks, is applied over the products under vacuum for a tight contact. Products are then loaded into a decoration machine at high temperature that turns inks into a gas that penetrates deep into the coated layer. Products are then taken out of the decoration machine and the used films are peeled off to reveal the images. At this point the products are completely decorated and ready for shipment.

No additional protection coatings are required.

Sandblasting

Unlike many powder coating companies, we do all of our sandblasting in house! We have an two industrial sandblasting systems that can handle any size part that will fit in our oven. Sandblasting, even on new parts, is extremely beneficial. To obtain excellent adhesion of the powder coat you need a completely clean and etched surface, sandblasting does exactly that. We believe that getting the part completely clean through sandblasting and our pre-treatment wash is the best way to ensure that your part lasts a lifetime. With sandblasting in house, it means a higher quality finished product with a quicker turnaround time since we can handle the sandblasting and powder coating. Even if you don’t want your part powder coated, stop in for all your sandblasting needs.

Four Stage Wash System

The most important process in powder coating is cleaning the item and prepping the surface in order to ensure the quality and longevity of the powder coating. Hoosier Powder Coating has a unique process that you won’t find at your normal powder coating supplier. We combine a high heat electric pressure wash with a multi-metal zirconium and etch cleaner that will remove all of the oils and completely clean the surface, which is ideal for powder coating. This hot pressure wash process is used in cleaning the toughest of oils. With that kind of clean, our quality of our powder coating is second to none! All of our aluminum parts go through this process, but most of our steel items are sandblasted.

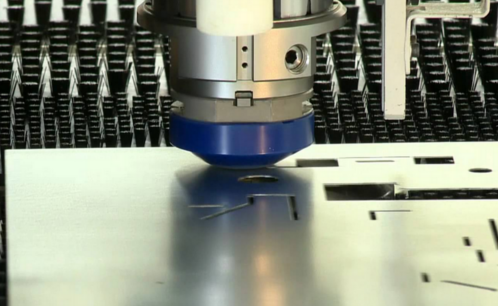

Laser and Plasma Cutting

The possibilities are endless with laser and plasma cutting! We laser cut plastic, wood, fiber, steel, aluminum and stainless steel. We can also etch all metals and offer wood burnings. For parts as large as 120″ long, our twin head CNC Plasma Cutter is able to cut burnouts to your design.

Brake Press Forming

With our CNC hydraulic brake press capabilities, multi-step bending operations can be achieved with accuracy and repeatability.

Welding

We offer MIG, TIG, and spot welding. Whether your part requires a single weld or is a multi-part weldment, we can meet your requirements with our in-house fixturing.